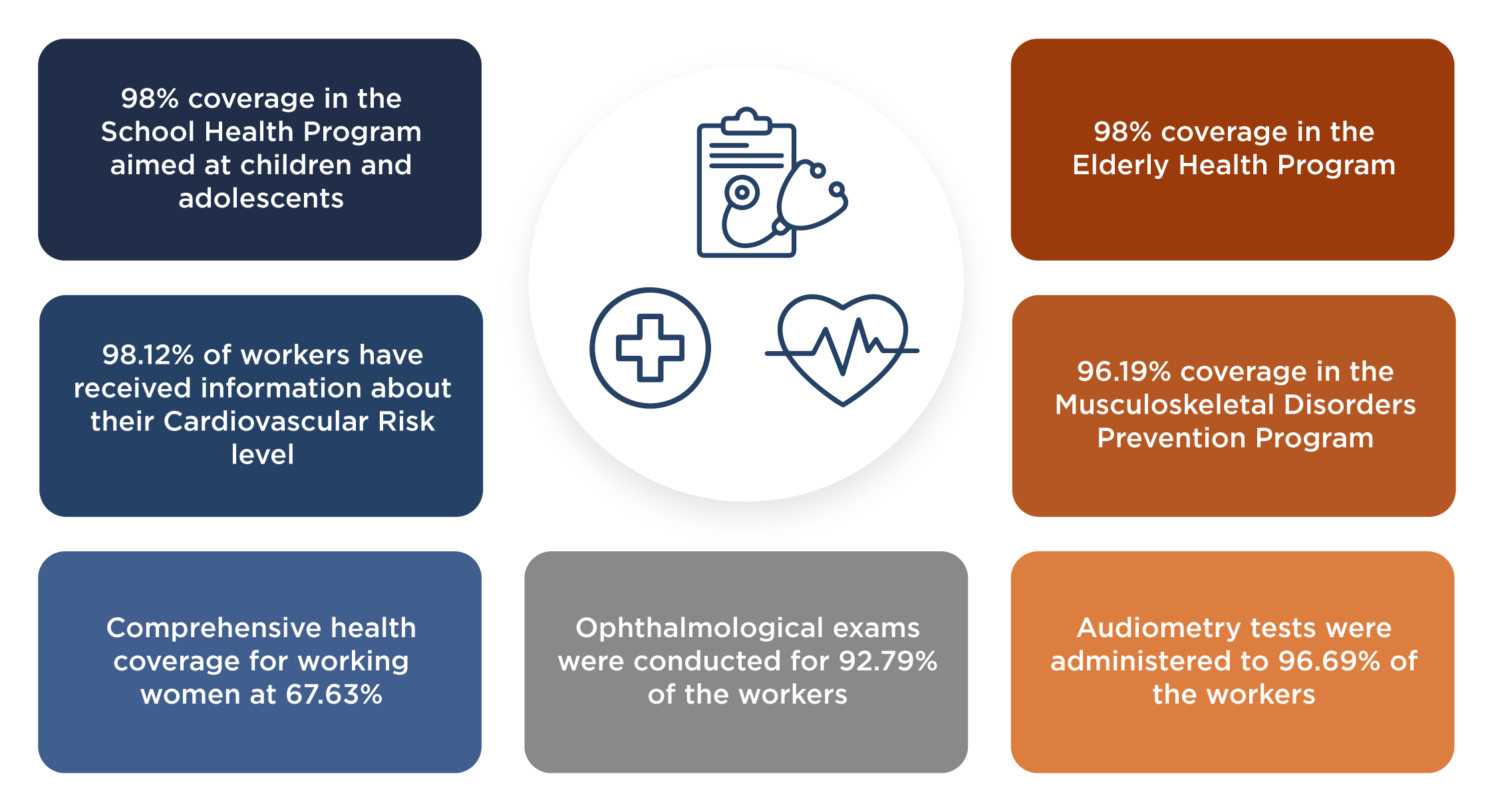

Health

In 2023, our health system continued to develop actions to protect the health of our workers and contractors working in the area of operations and in the offices of La Paz and Potosí.

Within the framework of institutional performance, we were able to secure reaccreditation of the health services of the local network granted by the Departmental Health Service of Potosí (SEDES) and certification of the Healthy Company Management System (SIGES) under Bolivian standard NB-512001. We are the only mining company in Bolivia with this certification at the moment.