Efficient Use

of Water

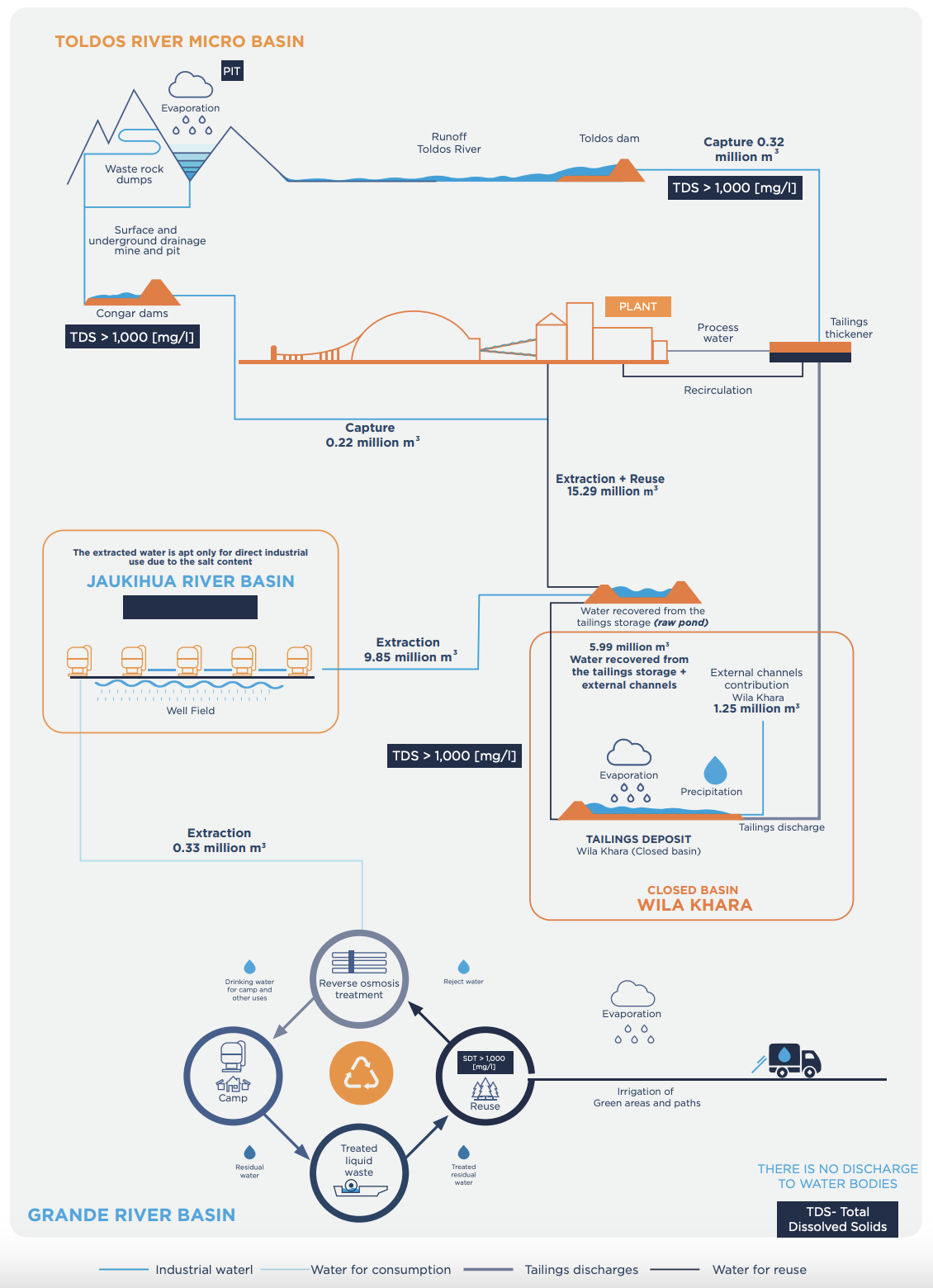

Elhe industrial water used in our mineral processing plant comes from pumping in the northern and southern well fields of the Jaukihua aquifer, located 10 km southeast of the mine. During the project's construction phase, a baseline study was conducted, identifying this water body as saline and unsuitable for human, animal consumption, or irrigation. Similarly, the groundwater extraction source is in an area with low demand for this resource, ensuring there is no water stress.

To prevent liquid discharges outside the operational area and dust emissions into the air, wastewater from the camp and dining hall undergo biological treatment until it reaches a quality suitable for reuse in the irrigation of re-vegetation plots and roads within the operational area.

Due to the arid conditions of the region and the demand for water for various activities, there are no discharges to water bodies. All these measures are part of the environmental control practices implemented across all our operations.